-

20 Years experience with Microspheres – Frilite

20 Years experience with Microspheres – Frilite

-

Expertise

The FRILITE® Group has over 20 years of experience with microspheres throughout the whole supply chain.

-

Quality

The FRILITE® Group will always aim to offer the best products and services and ensures highest quality standards.

-

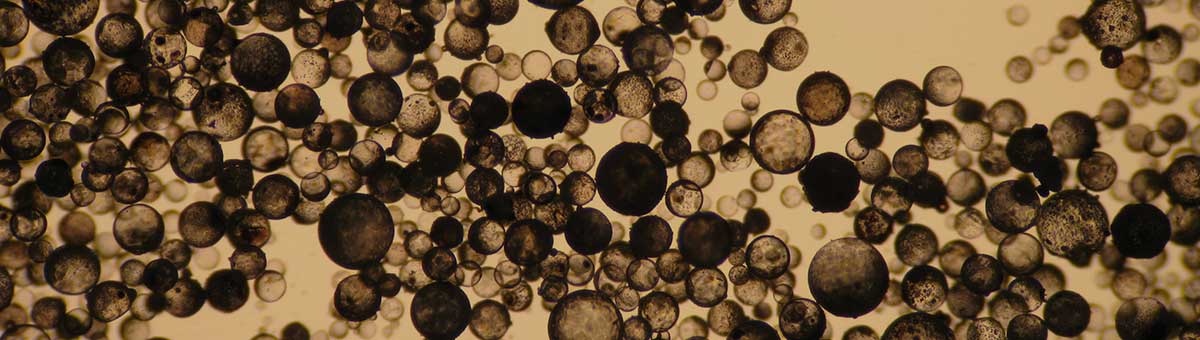

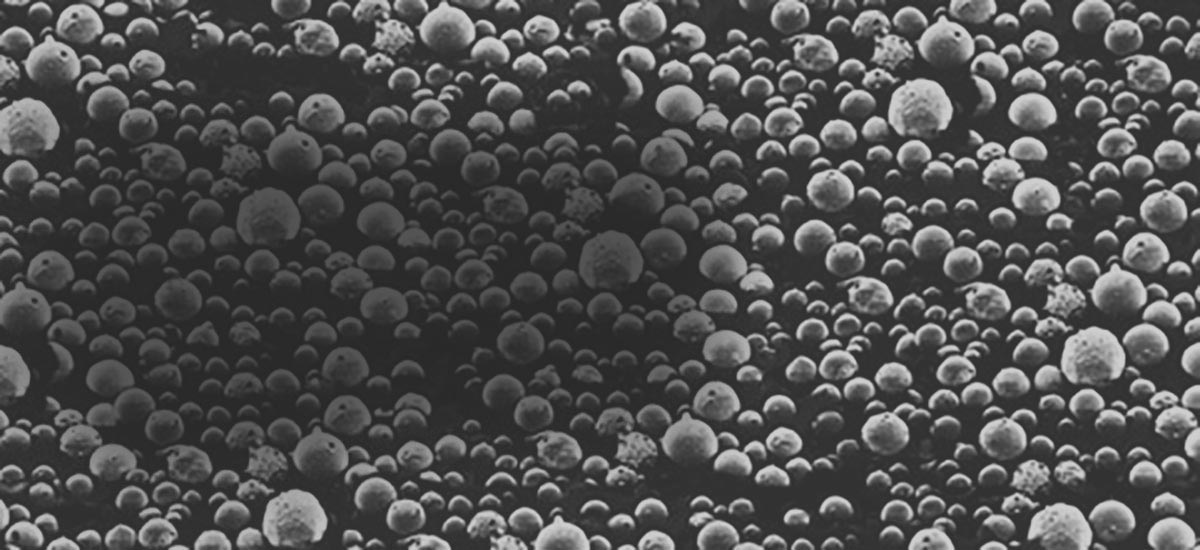

Microspheres

Microspheres are small spherical particles, available in different densities, colours and sizes.

-

Products

The FRILITE® Group offers a good quality product selection with different spheres.

-

Applications

The FRILITE® microspheres find use in many different applications like foundry, refractory, paints and many more.

-

-

Contact

For more information about FRILITE® microspheres, packaging or delivery options, do not hesitate to contact us via mail.

›

‹

- 1

- 2

- 3

- 4

- 5

- 6

- 7