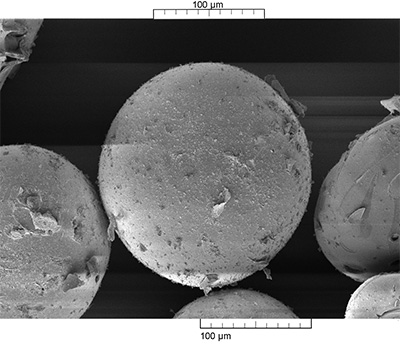

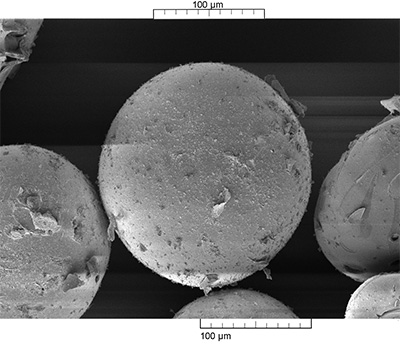

The FRILITE® W-Series cenospheres have an Al2O3 content between 30-40% and Fe2O3 contents of typically lower than 2%, which leads to an outstanding temperature resistance of over 1400°C. They are easily recognized by their white to off-white colour.

The FRILITE® W-Series cenospheres are available in sub grades between 5-500 microns and a bulk density of about 400kg/m³, specific gravity typically reaching from 0,7-0,85g/cm³ and featuring 90% survival rates at >3000 psi.

Applications

- Foundry and refractory

- Paints and coatings

More information

The FRILITE® K-Series cenospheres have an Al2O3 content between 34-39%, which leads to good temperature resistance of 1400°C. They are recognizable by their off-white colour.

The FRILITE® K-Series cenospheres are available in sub grades between 5-500 microns and a bulk density of about 400kg/m³, specific gravity typically reaching from 0,7-0,85g/cm³ and featuring up to 90% survival rates at >3000 psi.

Applications

- Foundry and refractory

- Caulks, sealants, putties and adhesives

- Concrete

- Wet ready-mix products

More information

The FRILITE® E-Series cenospheres have an Al2O3 content between 34-39% and Fe2O3 contents of typically lower than 2%, which leads to an outstanding temperature resistance of over 1400°C. They can be easily recognized by their white to off-white colour.

The FRILITE® E-Series cenospheres are available in sub grades between 5-600 microns and a bulk density of about 400kg/m³, specific gravity typically reaching from 0,7-0,85g/cm³ and featuring 90% survival rates at >3000 psi.

Applications

- Foundry and refractory

- Caulks, sealants, putties and adhesives

Standard Grades

More information

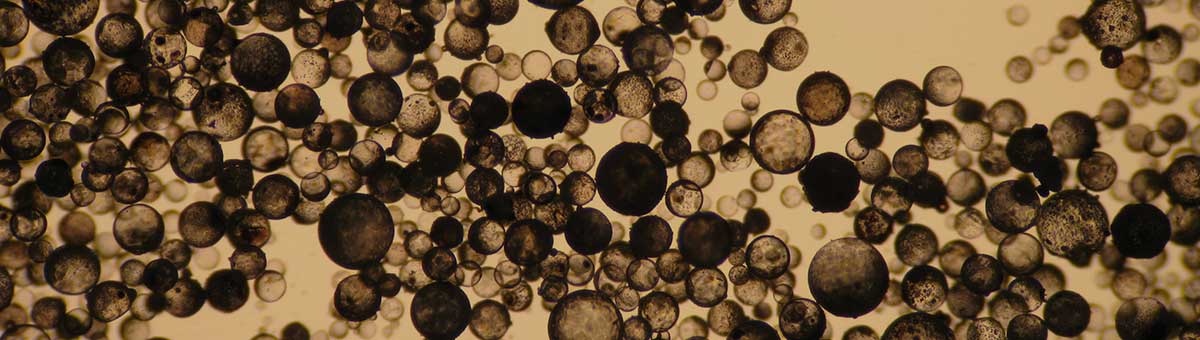

The FRILITE® G-Series cenospheres have an Al2O3 content between 26-32%, which leads to good temperature resistance of over 1150°C. They are recognizable by their off-white to grey colour.

The FRILITE® G-Series cenospheres are available in sub grades between 5-500 microns and a bulk density of about 400kg/m³, specific gravity typically reaching from 0,7-0,85g/cm³ and featuring up to 90% survival rates at >3000 psi.

Applications

- Foundry and refractory

- Caulks, sealants, putties and adhesives

More information

The FRILITE® P-Series are tiny hollow spheres made from natural occurring sand. The special production process does not use any fossil fuels and is simply based on a physical shape change, without the involvement of any chemicals, resulting in an environmentally neutral product.

The FRILITE® P-Series spheres are available in sub grades between 75-800 microns and bulk densities reaching from 80-600kg/m³.

Applications

- Plaster and dry mortar

- Lightweight concrete

- Lightweight panels

- Insulation coatings

- Sound dampening systems

More information