History

The story of the FRILITE® Group begins over 20 years ago:

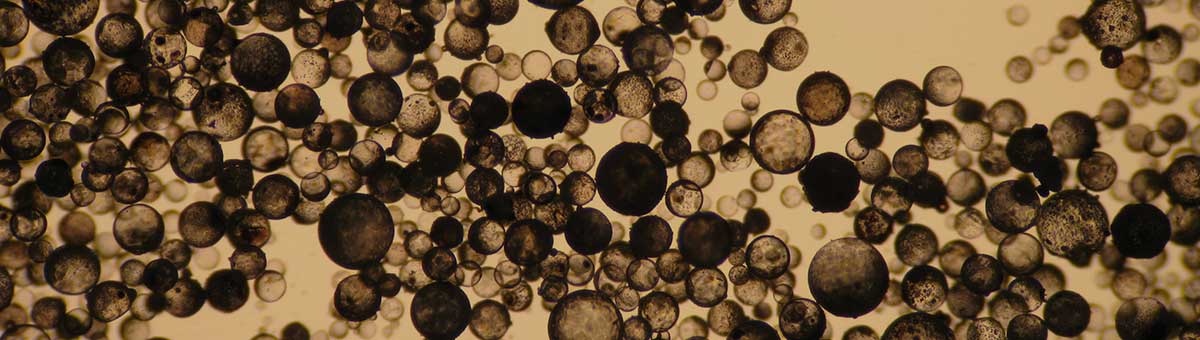

In 1998, we started to investigate the field of fly ash hollow microsphere (so called "cenospheres") in Eastern Europe and Northern Central Asia after coming across them in Great Britain and expecting a good potential of resources in those areas. In the following years, the team was focused on building up relations not only to coal power plants in that region but also to customers all over the world.

In 1999, the first microsphere skimming methods and equipment were tested, patented and put in operation. The sales of raw material started to international cenosphere brands like "Trelleborg Fillite" (now "Omya/Tolsa") and "Microfine Minerals" (now "LKAB Minerals").

In 2004, the installation of a new stationary microsphere production plant in Kiev region was completed, allowing further processing of the harvested raw materials into specific grades of high value cenospheres. This enabled the company to offer the customers a large variation of new product grades of best possible quality and cost efficiency.

Since 2005, all operational processes have been continuously organized and arranged in compliance with ISO 9001 quality standards.

In 2006, the company began to develop and sell cenosphere-based products like high temperature mortars, furnace cements and adhesives to domestic markets in eastern Europe.

In the following years a number of Cenosphere processing companies and plants were established and supported in eastern Europe including the participation in an IPO, the first and only one in this industry.

In 2011, the largest processing plant of its kind started operation in Belovo, Russia, after just 9 months of construction in cooperation with "JSC SUEK", Russia's leading coal exporter, reaching a nameplate capacity of 20 000t per year.

In 2012, a new record was set with 26 000t of harvested raw material in a short season of just 5 months, which brought the over all harvested raw material to over 150 000t.

In 2013, our stake in the Belovo processing plant in Russia was sold to our partners "JSC SUEK".

In 2014, together with multiple research centers the company began to intensify the focus on developing and evaluating equipment for the production of artificial microspheres which led to industrial prototypes and later to commercially viable solutions.

In 2015, the decision was taken to evaluate and establish a new production facility for artificial microspheres in middle Europe in order to get even closer to our customers and provide them clean and environmentally friendly product alternatives.

In 2017, the wonderful city of Thun, Switzerland, was chosen as location to build a new production facility, which led to the incorporation of "FRILITE SA".

In 2018, contracts with partners, authorities and suppliers were signed to establish the new production, development and office facilities with over all approx. 1800m².

In 2019, the introduction of FRILITE® was a consequent step to bring together our different microsphere businesses for the future and the related regrouping and rebranding will be completed within the year.

In 2020, the final construction permit for the project in Thun, Switzerland, has been granted. Due to Covid-19 the projected start of construction was postponed.